Container mobile houses are a type of housing that came into being at the right time. They are durable, safe, convenient, and easy to build. Initially, they were simply used as dormitories for workers on construction sites. Now, they are gradually being promoted in the market and given more meanings.

How to design a container house? BOXER container house professional design team will show you how to design a container house.

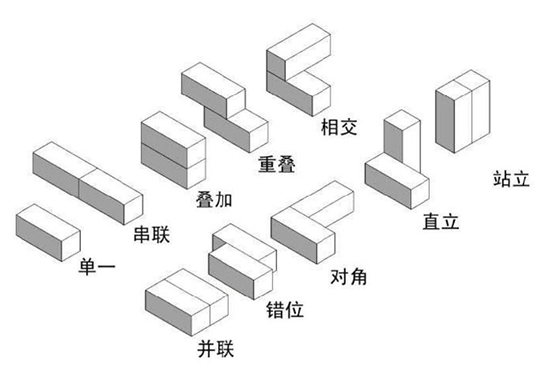

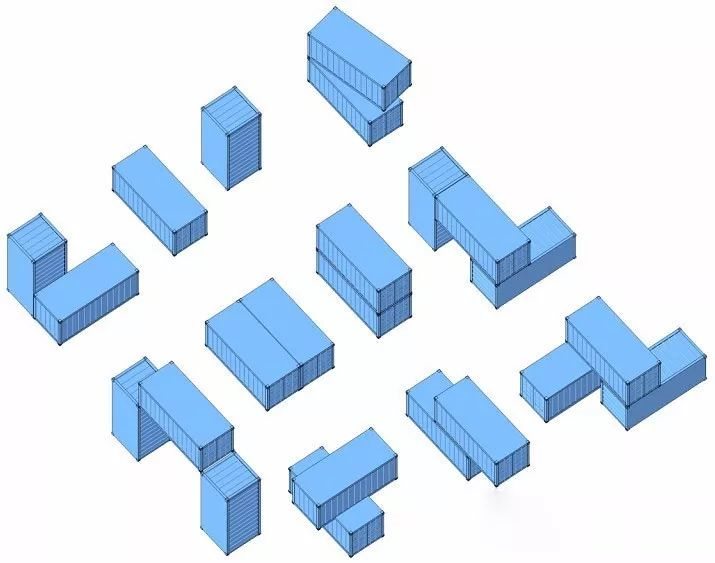

Combination design of container house

In the building, several containers are used to create overhead spaces, balconies, corridors, etc. at different angles and heights. The parallel, dislocation, and diagonal planes are used to create space.

The concentrated vertical space relationship commonly used in containers, with different lengths, can create some open-air balconies; angle rotation can produce some irregular balconies and rain shelters, and the staggered relationship can create balconies in different directions.

Plane splicing is a major factor that can determine whether a container building is attractive. Whether the space is easy to use and whether the sense of distance is well grasped all come from this.

Considering security factors such as anti-theft, the long side of the container itself can also be used as a good bodyguard. Remove the upper structural components and convert the lower components into rotatable ones, so that the container can be restored to its original state when closed. During the day, it can be opened to the ground to reveal the indoor scene. At the same time, the external container board can also be dropped to the ground to form a small entrance square and space for people to rest in the open air and drink tea.

Waterproof design of container house

1. When waterproofing membrane is constructed, after cleaning the base layer, apply adhesive on the reverse side of the membrane and the base layer, and stick and roll them from far to near according to the reference line, and finally check the joints. After completion, a water storage test should be done.

2. Waterproof coating, take "one cloth and two coatings" as an example: after the base layer is cleaned, apply one coat of coating, dry it into a film, lay a layer of glass fiber cloth matrix reinforcement material, and apply a layer of coating on the flat surface to fix it. After drying, proceed to the next step of roof waterproofing construction.

3. Laying a rigid waterproof layer should be carried out about two days after the completion of the first flexible waterproof layer. It is mainly based on high-grade fatty acid mortar waterproofing agent, cement, sand, fine stone aggregate, and fiber. The thickness of the waterproof layer should be 20-30mm.

4. The top is covered with glass, aluminum plate, and color steel plate, which is waterproof and has ventilation and heat insulation effects. Install steel keels on the top, cover aluminum plates, glass, color steel plates and other waterproof layers, and apply glue. The above is based on the customer's usage requirements and budget cost selection.

Interior/exterior wall/exterior top treatment design of container house

Inside the container: In order to meet the requirement of fireproof insulation of walls and ceilings for no less than 45 minutes, the interior is decorated with glass rock wool sandwich panels with a thickness of no less than 50mm. Walls/ceilings are usually decorated with European pine boards, gypsum boards, cement fiber boards, polymer assembly boards, aluminum alloy carved boards, anticorrosive wood, etc. Outside the container: The walls are generally decorated with exposed graffiti, glass, aluminum plates, anticorrosive wood, cement fiber boards and other curtain walls. The top of the container is waterproofed with coiled materials, plus aluminum plates, color steel plates, anticorrosive wood floors and other top treatments.

Thermal insulation and sound insulation design of container buildings

Depending on the environmental climate of the project site, the insulation materials used for insulation will also be different. The interior of the container is sprayed with polyurethane foam, and 50-100mm glass rock wool boards are installed to prevent moisture and corrosion, and to insulate heat and sound. Air conditioning is installed indoors in the south, and floor heating is installed in the north; the outer layer is covered with decorative materials, such as European pine board, gypsum board, cement fiber board, polymer assembly board, etc.

The commonly used concentrated vertical space relationship of containers is of different lengths, which can produce some open-air balconies; angle rotation can produce some irregular balconies and rain shelters, and the dislocation relationship can create balconies in different directions.

Here BOXER shows you a high-quality container house design case.

Flying Box Villa

Designed by Gillet's studio 2A Design, the Flying Box house is located in a rural village near Rennes, France. To reduce overall costs and the required construction period, the house uses a system developed by local company B3 Ecodesign, which converts shipping containers into modular homes at its Rennes factory.

Flying Box Villa is a surprisingly small low-cost house completed on a tiny plot of land.

How to install and create a perfect container house? This is an important part after the design.

Installation method: The container mobile house is similar to building a building. The surrounding and partition wall foundations are leveled. It is best to use reinforced concrete, which is relatively strong.

The hidden project of the container mobile house refers to the parts that will be covered by the next process after the previous process is completed during the construction process. After all the parts are completed, they cannot be inspected. For room decoration, "hidden projects" are the key. If the "hidden projects" are not done well, no matter how beautiful the surface decoration is, it is in vain.

"Hidden projects" can be divided into water installation, electrical installation, moisture-proof, waterproof and other projects. Each of these projects cannot be ignored. If any link goes wrong, it may cause serious economic losses and even harm personal safety. The construction process and material identification of waterproof projects can avoid unnecessary economic losses.

The BOXER container house is highly completed in the factory. The main components, water and electricity, and interior decoration can be completed in the factory to minimize the construction period on site. Achieve the effect of not being affected by weather.

Container houses were originally just a simple means of transportation, but when people found that they could also be used for living, they became unstoppable. This low-key new type of building is not only low-carbon and environmentally friendly, but also exudes a unique artistic atmosphere. As long as you pass by it, you will be deeply fascinated by it, which is inseparable from excellent design.